CNC Programming for Mill Turn has never been this easy!

Mill Turn is a complete

multitask CAD-CAM software that combines all of the powerful CNC programming functionality of both mill and lathe into a single

streamlined C-axis machining solution. BobCAD-CAM’s multitask CNC software delivers high performance features in an easy to use interface

designed to meet the complex programming demands of mill turn machining. Mill Turn is a complete

multitask CAD-CAM software that combines all of the powerful CNC programming functionality of both mill and lathe into a single

streamlined C-axis machining solution. BobCAD-CAM’s multitask CNC software delivers high performance features in an easy to use interface

designed to meet the complex programming demands of mill turn machining.

The new Mill Turn CAD-CAM software from BobCAD-CAM is one of the easiest and most efficient multitask machine programming solutions on the

market today providing everything from simple 2-axis turning and 3- & 4-axis milling strategies to full 4- & 5- axis simultaneous milling

capabilities.

Incorporating a full range of sophisticated and fully associative machining strategies through a simple wizard driven interface, Mill Turn

makes programming quicker and easier. BobCAD-CAM gives you the control to easily program the non-perpendicular multi-axis tool movements

required to machine intricate features and compound angles found in many complex parts such medical components, complex valves, tool holders,

oil drilling tools and many others.

CAD-CAM Software Features for CNC Mill Turn Machines

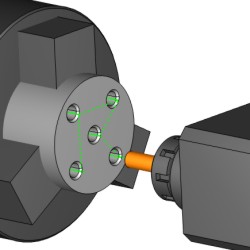

2-Axis Turning & Live C-Axis

C-axis milling supports positioning and

contouring motion on the OD and part face. Use it with indexing, wrapping, and rotary toolpaths to drill holes, cut pockets and more on the

centre line around the part diameter. C-axis milling supports positioning and

contouring motion on the OD and part face. Use it with indexing, wrapping, and rotary toolpaths to drill holes, cut pockets and more on the

centre line around the part diameter.

|

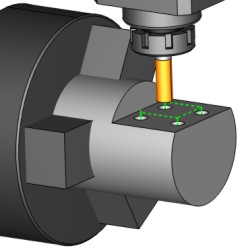

Y-Axis Milling Support

Y-axis gives you the ability to perform milling operations both on and off the centre line, allowing you to execute 2-, 3- and 4-axis

milling and cross drilling on the OD and part face. |

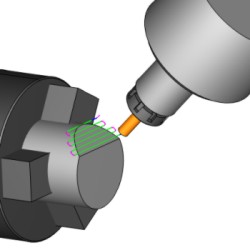

5-Axis Milling Support

B-axis (5-axis) milling head programming can be used with single spindle and sub-spindle machine setups to give you the flexibility to

best target your part when performing facing, pocketing and hole drilling operations. |

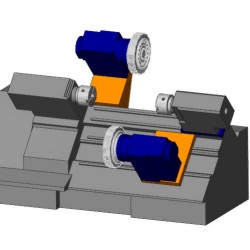

Mill Turn CNC Machine Compatibility

The software supports nearly all mill turn, multitasking, live-C and lathe equipped with live tooling machine setups that can include

multiple spindles, multiple turrets, milling heads, programmable steady rests, programmable tailstocks, part catchers and machines with B-

(5-axis), C- and C-Y axis capabilities. |

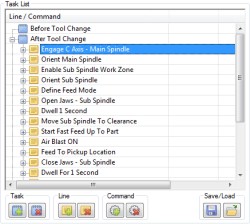

MDI Programming

MDI programming within the multitask CNC software allows you to set up the sequence of actions performed before tool changes, after tool

changes or after an operation is completed. |

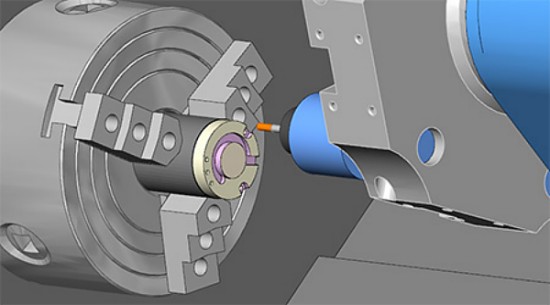

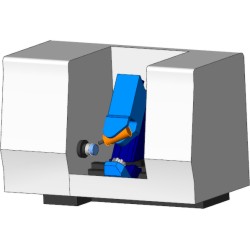

Full Machine Simulation

Utilise your machine’s kinematics and full

machine and tool definitions to test and confirm your mill turn programming before ever cutting a chip in this collision rich machining

environment. Utilise your machine’s kinematics and full

machine and tool definitions to test and confirm your mill turn programming before ever cutting a chip in this collision rich machining

environment.

|

We are happy to demonstrate to you how the software works and show you what benefits we can help you

incorporate into your shop so that you can get a better return from your new technology investment. Call Today!

|