Predator MDC ● Machine Monitoring & Data Collection

|

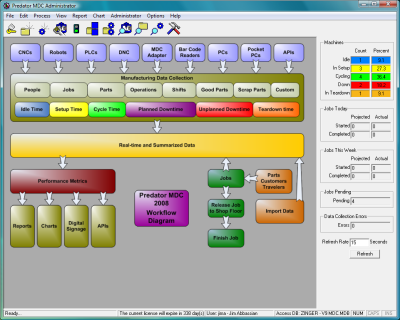

Predator MDC is real-time software that automatically collects, reports, charts and processes real-time shop floor

manufacturing data including cycle time, idle time, setup time, teardown time, machine downtime and more. Predator MDC improves manufacturing

by supplying accurate shop floor productivity metrics to improve operations and to make better decisions. |

Available in 2 Editions

- Predator MDC Express is designed to manage manual or paper based MDC processes.

- Predator MDC is designed to manage real-time MDC processes

Every Predator MDC/x license includes Predator DNC/x for integrated Send to CNC, Receive from CNC and drip-feed operation.

FEATURES

Automatic and Manual Data Collection

Predator MDC supports automatic, error-free and unattended machine monitoring for events such as job start and end, setup start and end,

cycle start and end, to name a few of the events that can be monitored. This type of data is collected automatically using software, hardware,

custom macros and other methods without requiring operator training or input.

Predator MDC also supports manual monitoring of events that are initiated by machine operators such as machine logon/offs, downtimes, and scrap

reasons. Predator MDC can be used to manually collect data using several methods including Remote Request™, swiping bar codes, touch screen PCs

or standard PCs.

One Network to Monitor all your CNC Machines, Robots and PLCs

Predator MDC supports up to 4,096 CNC machines, robots and PLCs per PC for simultaneous cycle time, setup time, teardown time, downtimes with

reasons, good parts, scrap parts with reasons and an unlimited number of user defined events.

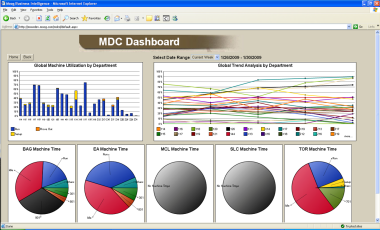

Real-Time Machine, Job and Part Dashboards

Real-Time Machine, Job and Part Dashboards

Keep score of your shop floor productivity with Predator MDC. Every second is tracked per machine, job, part, operation, shift and person. A

real-time scoreboard displays current machine, part, job, operation and personnel status. Multiple engineers, supervisors and managers can view

the scoreboard form any networked PC. Leverage the power of the Internet and VPN from anywhere in the world to see the status of your shop

floor.

Multiple Plant Support

Predator MDC supports an unlimited number of plants or buildings right out of the box. Multiple plants can share a single database for

enterprise wide reports and charts or each plant can have a separate database. Compare plants or compare buildings to improve productivity.

Organise your machines by grouping them per building or cell. Network PCs, CNCs, PLCs and robots to create an entire real-time shop floor

machine monitoring and data collection system.

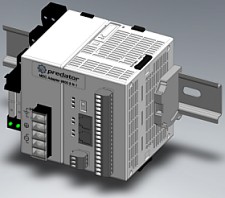

Predator MDC Adapter

Hardware based data collection for older CNCs, manual machines and other equipment are supported. Predator

MDC Adapters are DIN rail

mounted and can be wired into signal lamps, light towers, extended M functions or any digital input or output. Predator MDC Adapters are available

in 5, 12, 24, 48, 110 and 230 volt editions. MDC Adapters are DIN rail

mounted and can be wired into signal lamps, light towers, extended M functions or any digital input or output. Predator MDC Adapters are available

in 5, 12, 24, 48, 110 and 230 volt editions.

Unlimited Number of Data Collection Events

An unlimited number of data collection events such as cycle start, cycle end, good part, scrapped part, etc. can be collected via 16 different

methods designed to maximise automatic machine data collection and minimise manual data collection. (The Predator MDC Adapter pictured left

converts electrical input from any machine into text messages. To date CNC machines, manual machines, robots, band saws and many other machines

types have benefited from the power of the Predator MDC Adapter.)

1,300+ Reports and Charts

1,300+ Reports and Charts

Over 1,300 reports and charts provide unique insight into the productivity and efficiency of each manufacturer. The flexibility of the reporting

and charting options within Predator MDC converts the volume of data collected into concise reports and charts to identify issues and drive

improved productivity. (Custom reports and charts can be created with Crystal Reports, Microsoft Access, SQL Reports and Oracle Reports.)

Supports Wireless, Ethernet, RS-232 and Parallel I/O

Data collection via 802.11 wireless, Ethernet, RS232 and even parallel inputs are supported with Predator MDC.

Open API and Database Architecture

Integrate your ERP and MES system with Predator MDC's open APIs (application programming interface) with 300+ methods all fully documented.

Develop ERP and shop floor validation, flow part and job numbers from ERP directly into Predator and numerous other automation projects can be

completed with C#, C++, VB.Net, VB6, VB script, Windows Script, Delphi and other compatible programming languages. Predator MDC is based on an open architecture client/server database standard. Select from Microsoft Access, Microsoft SQL Server, or Oracle. Integrate your ERP and MES system with Predator MDC's open APIs (application programming interface) with 300+ methods all fully documented.

Develop ERP and shop floor validation, flow part and job numbers from ERP directly into Predator and numerous other automation projects can be

completed with C#, C++, VB.Net, VB6, VB script, Windows Script, Delphi and other compatible programming languages. Predator MDC is based on an open architecture client/server database standard. Select from Microsoft Access, Microsoft SQL Server, or Oracle.

Includes Predator MDC Executive

Predator MDC Executive is an easy to use browser based dashboard which provides an executive overview without having to install Predator MDC

software. (Supports Microsoft Internet Explorer, Mozilla Firefox, Google Chrome and Apple Safari.)

|